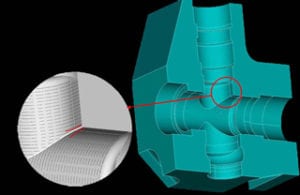

Engineers have long ago identified the problem with fluid end designs; intersecting cross bores of fluid ends concentrate stress at the corners. Fluid end intersecting bores concentrate or focus stress at each of the four intersection corners.

Engineers have long ago identified the problem with fluid end designs; intersecting cross bores of fluid ends concentrate stress at the corners. Fluid end intersecting bores concentrate or focus stress at each of the four intersection corners.

The Advantage of Oblong Borings

The Advantage of Oblong Borings

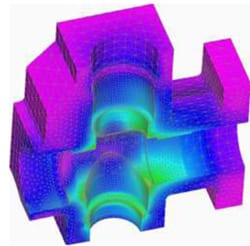

When the intersecting bores are stretched so that the bores become oblong. The curvature lines enter the flat section of the oblong bore, the curvature lines now run parallel; never to meet. Stress is now dispersed over the flat sections of the oblong bores.The computer FEA program calculated a maximum stress on this fluid end at 15000 psi internal pressure of 50963 psi Von Mises stress or 47% of the stress on a conventional fluid end. This lower stress can improve fluid end life as much as 100%.

The Vangard Fluid-End design has been operating in the field for a couple of years. The field data has proved the oblong bore concept to be correct and significantly extend fluid-end life (compared to standard fluid-ends).

The Advantage of Oblong Borings

The Advantage of Oblong Borings